Our vision is to be a world-class business, trusted to transform the most challenging sites into exceptional places and to maximise our positive impact on society, the economy and the natural world.

Our Vision 2030

Our Vision 2030 is Berkeley Group's ambitious responsible business strategy for the future.

Berkeley has always been driven by a clear purpose - to build quality homes, strengthen communities and improve people's lives. We have established a unique culture, and strong values that shape the way we work.

Building on these foundations, in 2010 we created a long-term strategy to guide our business: Our Vision. Since then, it has pushed us forward and helped us lead the industry in important areas like customer satisfaction, tackling biodiversity loss, and taking climate action. Read more about a decade of success here.

This extract from the Berkeley Group’s 2025 Annual Report provides an update on progress towards meeting our targets across each of our ten strategic priorities and details highlights for the period May 2024 to April 2025.

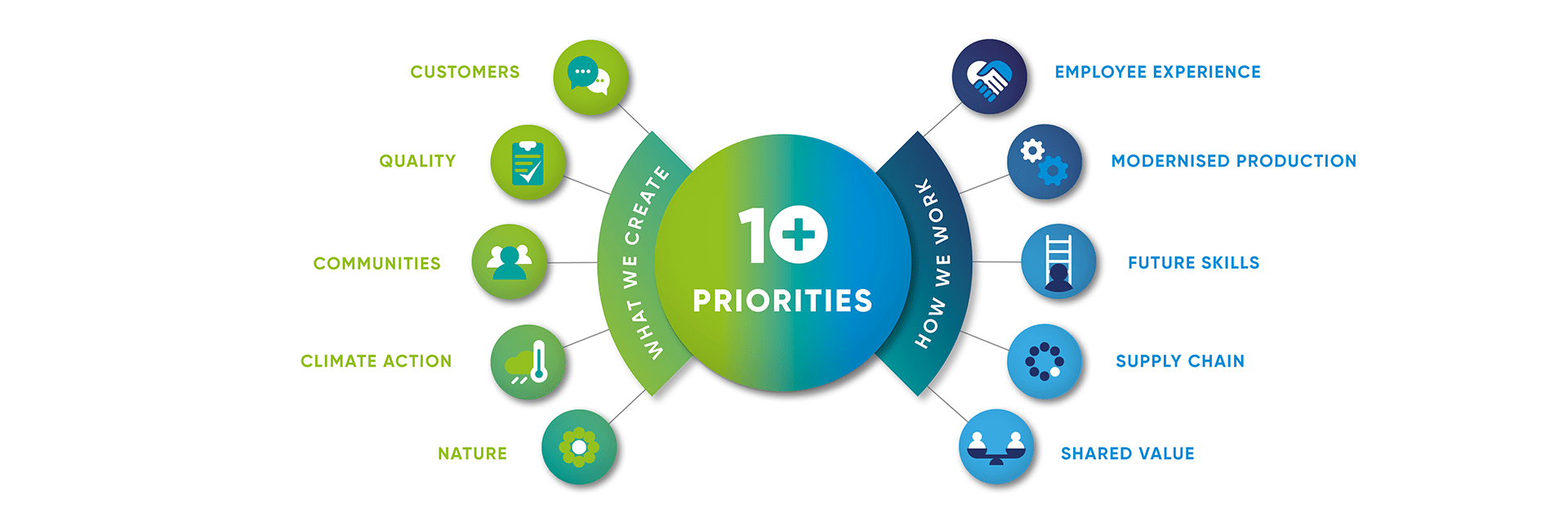

Our 10 Priorities

We have identified ten strategic priorities that will help us to transform tomorrow - through both what we create, and how we work. To pinpoint these topics a materiality assessment was carried out in 2020 by an independent expert consultancy, with a methodology based on international best practice from the Global Reporting Initiative. Read more here.

Now at the halfway point of Our Vision 2030, we are planning an updated materiality study to confirm the priorities and our strategy remains relevant, and accurately reflects the most important issues for Berkeley and its stakeholders.

Each priority has a goal and you can read more about what we're doing to achieve it, as well as our progress, by following the links below:

What We Create

Places that stand the test of time:

How We Work

Exceptional people and resources:

2024/25 Highlights

A Net Promoter Score (NPS) of +81.6, compared to an industry average of +59 (on a scale of -100 to +100)

87% of operational energy consumption is from renewable sources, including 100% renewable electricity for UK activities

Our biodiversity net gain sites are set to create more than 1,200 acres of new or improved natural habitats

95% of completed homes achieved an EPC rating of B or above

Our Annual Injury Incidence Rate (AIIR) is 102, compared to an industry average of 306

8.7% of employees in 'earn and learn' roles as graduates, apprentices or sponsored students

Awards, Accreditations & Partnerships

Britain’s Most Admired Company

Echo and The London Stock Exchange

Outstanding Achievement Award

In-house Research

Number one UK Housebuilder for Build Quality

HomeViews

Best Large Housebuilder

WhatHouse? Awards 2024

Gold Member

The 5% Club

Philanthropy Award, with the Berkeley Foundation

Better Society Awards 2025

Latest News

Hartland Retreat Unveiled as a Sanctuary for Wellbeing

Men’s Sheds has officially unveiled Hartland’s Retreat, a vibrant new garden space designed to support wellbeing, creativity and connection among its members.

Full Year 2025 Results Announced

Berkeley Group Holdings plc announces its audited results for the year ended 30 April 2025.

Public-Private Partnership Delivers First Affordable Homes and Two Bridges to Reconnect West Ham at Twelvetrees Park

Berkeley Group, in partnership with the Greater London Authority (GLA), London Borough of Newham, Homes England, and Peabody, has delivered the first 110 affordable homes and two pedestrian bridges at TwelveTrees Park, West Ham

Hundreds Celebrate Opening of Riverside Park at Heron Wharf, Poplar

More than 400 local people came to Heron Wharf on Saturday to celebrate the official launch of a new public park.

Berkeley Backs Government’s Homebuilding Mission With Plans for 10,000 Extra Homes

Berkeley Group has endorsed the Government’s target to deliver 1.5 million new homes during this Parliament.

Berkeley Group Named Top Graduate Employer for Property and Housebuilding

Berkeley Group has been named the top Graduate employer in Property and Housebuilding sector by The Job Crowd.